FILAMENTS IN SPECIAL MATERIALS

NYLON

Compared to other materials (PLA and ABS), the layers have a very low risk of delamination, due both to a better linkage between them that for a greater elasticity of the material. Therefore it is difficult to break when exposed to stress. It is generally much more robust, but also lighter.

Has a very smooth surface and sliding which makes it suitable for parties who must scroll to the mutual contact (bearings, hinges, screws, male/female).

Very resistant to degradation. Avoid the contact with very acidic substances that would damage the bond between the layers.

You can not paste separate pieces for chemical incompatibility.

Harmless to the body, does not contain organic materials and is indigestible.

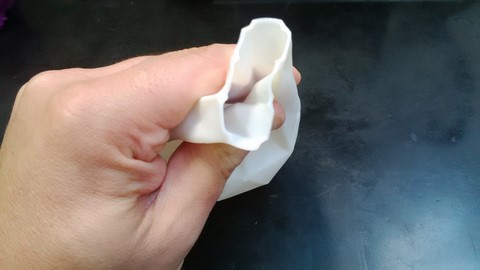

TPE - TPU

The filament in FLEX is a flexible material with a certain elasticity. It has functional characteristics similar to the rubber and you can print various objects such as bracelets, seals, and other objects gummy.

Colors: blue, white, black, red and natural.

LAYWOOD

LAYWOOD is a material that allows you to print objects that have the appearance and the smell of the wood. LAYWOOD is a filament composed of 40% recycled wood combined with polymer binders that allow the melting and extrusion such as PLA and other filaments used in 3D printing. Depending on the temperature of the extrusion surface is darker or lighter.

Material: Recycled wood (40%), polymer binders.

Melting point: 180 °C effect light color, 245 °C dark effect dark color.

LAYBRICK

LAYBRICK is a material that allows you to print objects that have the appearance of sandstone. It is an ideal material for architectural and landscapes models. This filament can be colored and sandpapered and presents no visible warping. Depending on the temperature of printing the object surface can be more or less smooth.

Material: Mixture of harmless worked chalk and co-polyesters.

Melting point: 165 °C for the smooth surfaces, higher temperatures up to 210 °C for rough surfaces.

HIPS

HIPS is a plastic similar to ABS for strength and extrusion temperature. It is soluble with limonene at room temperature, can be used as support material with 3D printers equipped with dual extruder. HIPS (High Impact Polystyrene) is thermoplastic material consisting of polystyrene and styrene-butadiene rubber (rubber or SBR). Compared to common polystyrene, HIPS presents the following peculiarities, due to the presence of the rubber SBR: higher elongation at break (HIPS is able to undergo a deformation even higher than 40% before breaking), greater impact resistance and opacity. This filament comes sealed in a bag with desiccant to maintain freshness.

Material: High Impact Polystyrene

Melting temperature: ~235 °C

PET (PETG)

PET (also known as Polyethylene Terephthalate) in its original state is a transparent, colorless and crystalline material. PET is a fairly stiff and very lightweight material, which is very strong and impact-resistant. These characteristics make the material particularly suitable for light products. With higher temperatures are obtained "dark color" objects and sometimes slightly fibrous. At lower temperatures, the surfaces are generally smooth.

Material: Polyethylene Terephthalate

Melting point: 210 °C