KLONER3D®240TWIN

Ideal for the production

KLONER3D®240TWIN is the great innovation of the family of 3D printers KLONER3D®. Provided with dual arm is ideal for quickly creating, in half the time, of architectural or mechanical models and pre-series.

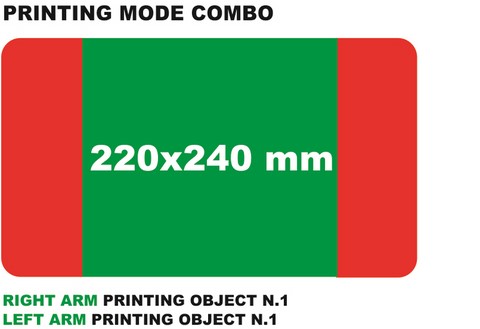

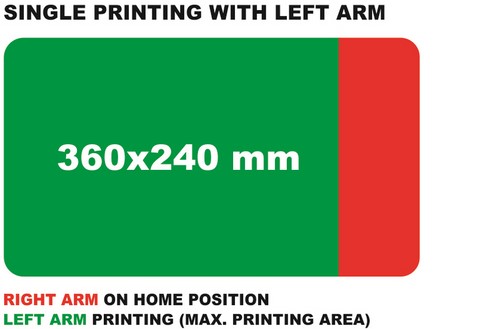

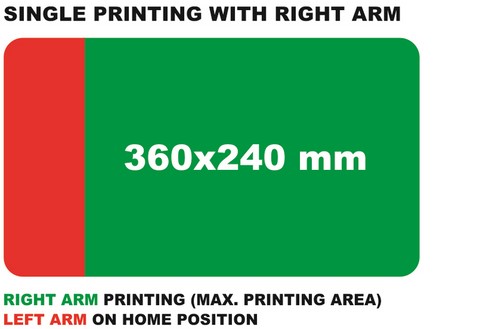

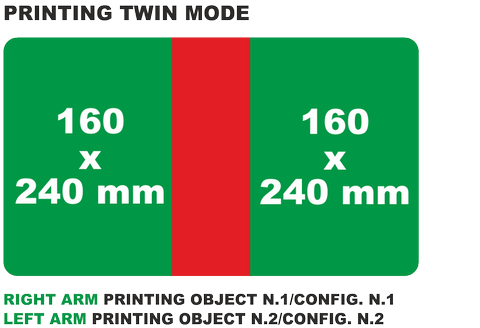

The arms work independently. You can print different objects simultaneously, or you can use the entire print area by one of two arms for the realization of an object of larger size.

- No mechanical calibration.

- No maintenance by the user.

- Ready for use.

- Print environment enclosed with work area at temperature controlled.

- Easy loading print material.

- Interchangeable head.

Technical Specifications

DIMENSIONS

external dimensions (WxDxH)

690x460x600 mm

weight

39 kg

MECHANICS

structure

ground aluminium frame

external cover

metal sheet, PVC and plexiglass

print bed

heated adjusted aluminium

axis movements

XY linear axis

Z double linear axis

PRINTING

print technology

Fused Filament Fabrication (FFF)

print area (XYZ)

mod. 1 360x240x140 mm (12,10 lt)

mod. 2 360x240x140 mm (12,10 lt)

mod. 3 160x240x140 mm (5,40 lt)

mod. 4 220x240x140 mm (7,40 lt)

mod. 5 500x240x140 mm (16,80 lt) (mod.Autodesk Netfabb)

min. layer height

0,035*-0,05 mm

motion resolution

XYZ 0,01 mm

dual extruder

yes**

filament diameter

1,75 mm

3* mm

nozzle diameter

0,3*-0,5-0,8* mm

printable materials

multimaterial

* Depending on the print head.

**With dual extruder the printing area is reduced.

SOFTWARE

software

windows, mac and linux

file types

STL, OBJ, GCODE

OPERATING REQUIREMENTS

electric

100-240 Vac 50-60 Hz; ~450W

operation

temperature: 15°C-35°C

humidity: 15%-55%

Mod. 1

Mod. 2

Mod. 3

Mod. 4